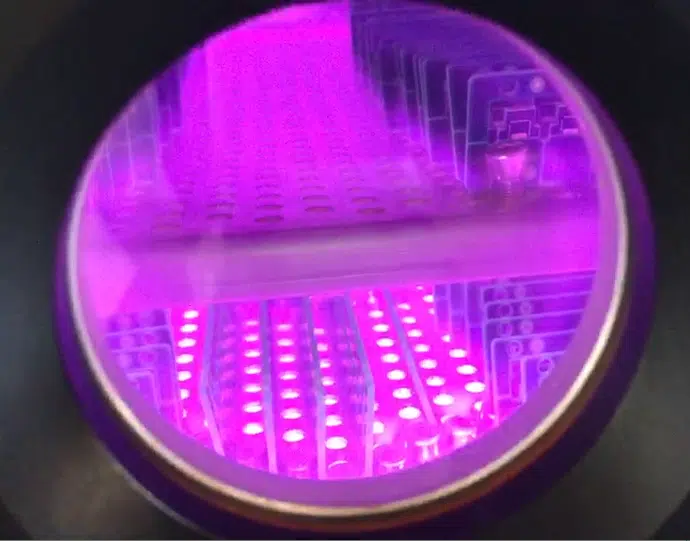

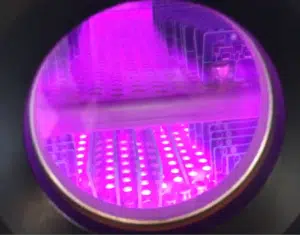

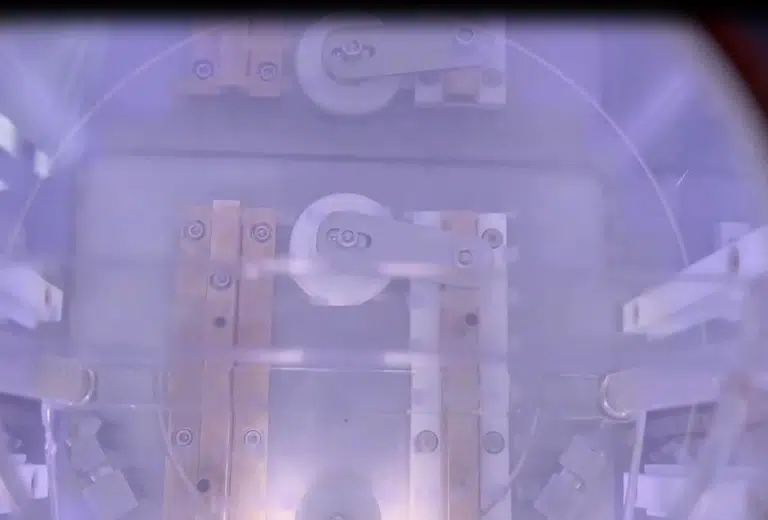

GD-30 Plasma Cleaning Machine is consist of the plasma cleaner host and a vacuum pump. The vacuum cavity size is 350(L)*320(W)*320(H) mm, and the equipment size is 870(L)*740(W)*1540(H) mm. What’s more, we can customized the layer, cavity size and the power frequency with customers. With PLC and touch screen control, it’s very convenient.

It can be used for large-scale continuous production and various of products.

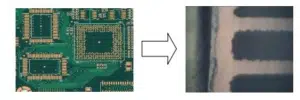

PCB, called printed circuit board, is the carrier of electronic components and electrical appliances connected with each other. There are three categories: single panel, double panel and multi-layer board. The production process of multi-layer PCB is very complex, mainly including PCB layout, core plate making, core plate drilling and inspection, lamination, drilling, copper chemical precipitation of the hole wall, outer PCB etching and other processes. The main function of the plasma cleaning machine is to remove the residual glue of the hole wall and improve the activity in the hole after drilling, so that the liquid can fully clean the hole wall and improve the conductive performance of PCB.

In fact, the multilayer plate is made of copper clad plate (core plate), copper foil and semi-solidified plate . Taking 4 layers of PCB as an example, it is made of 1 piece of copper clad plate and 2 pieces of copper foil, and then bonded with semi-solidified plate. Semi-cured sheet is generally epoxy resin material with insulation, under the action of pressure can make the core plate and copper foil fixed. In order to connect different layers of lines will be drilled on the PCB, and then electroplating in the hole wall, so that the hole wall can be conductive. Residual glue is the epoxy resin glue remaining on the hole wall after drilling. The epoxy resin glue is an insulating impurity.

If it is not removed thoroughly, it will lead to the following four problems.

- Combined with other agents produce greater pollution

- The corrosion of lines and devices, damage the electrical performance of components

- Impact the effect of plating and chemical copper, cause quality hidden trouble

- Bond between copper foil and copper plate is not strong, make liquid deep, affect the subsequent etching.

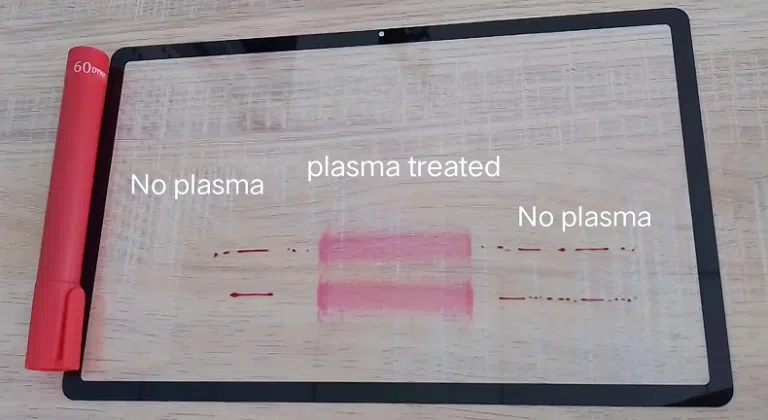

Plasma cleaner can remove part of the epoxy resin glue, but can not be thoroughly cleaned, so it must use potassium permanganate and other acid for thoroughly remove. Due to the active function of the plasma, the activity of the pore wall surface is changed and improving the hydrophilic nature of the surface, so that the liquid liquid can be cleaned more thoroughly. Plasma cleaning is divided into three aspects, activation, removal and decontamination. First, the plasma produced by nitrogen electrolysis makes the PCB surface in an active state; Second, the plasma produced by mixing oxygen and CF4 reacts with the adhesive residue and glass fiber; Three, when oxygen is the main gas, the oxygen ion and the residue on the material surface to achieve the cleaning effect.