Wire & cable need pass inkjet code process before finished, such as inkjet the production batch number, specification and date. In general ,the material of wire and cable is rubber, PVC, PE, nylon, while these material surface attachment ability is very low, after coding , the inkjet code is easy to blow off from cable surface. In dealing with this problem, some cable manufacturers have made a variety of attempts, such as replacing the ink with higher adhesion or the use of hot pressure method to imprint labels, etc., but these methods not only can’t solve problem fundamentally but also involve other problems. Although replacing the ink with higher adhesion, it will lead to the failure of the inkjet printer, and the thermal pressure rule is low efficiency, poor quality and easy to cause environmental pollution.

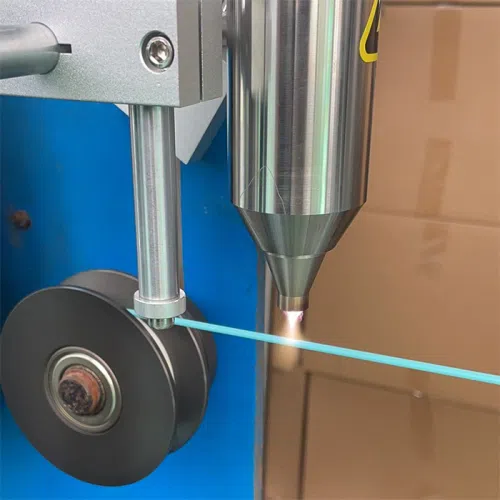

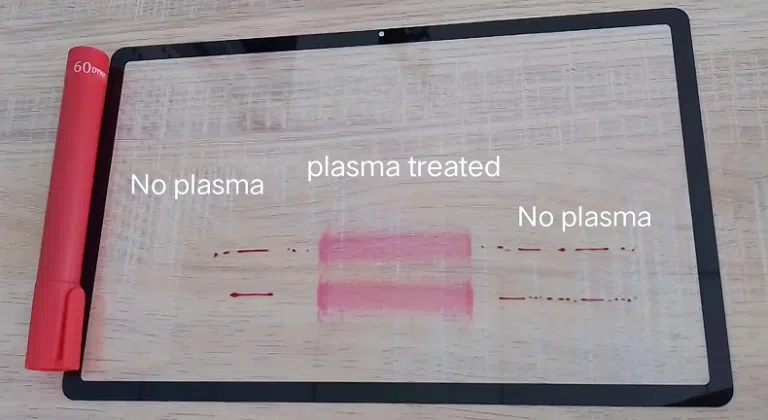

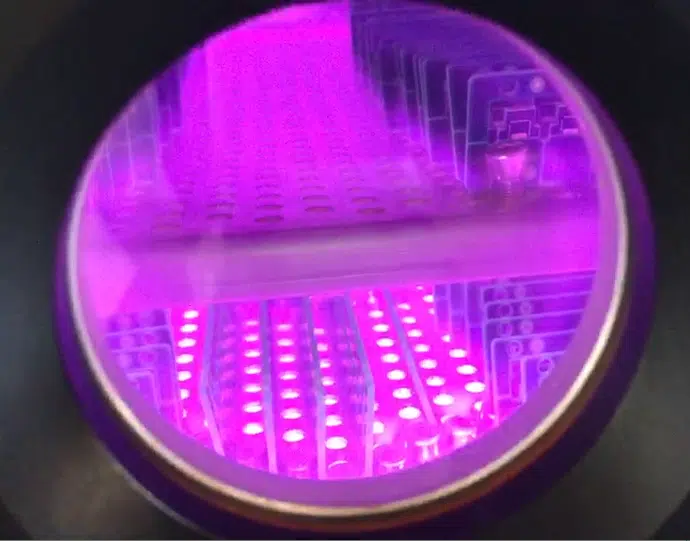

While the plasma treater can solve the problem easily. Some people ask plasma as corona. It can treatment rubber, silicone, metal, glass and other material which material with low energy, low tension and poor hydrophilic. After plasma treatment, these materials surface energy and tension will be improved. When the plasma bombard the wire and cable surface, the surface activity of the material changes from poor attach to easy adhesion that fundamentally solving the problem of easy to fall off.

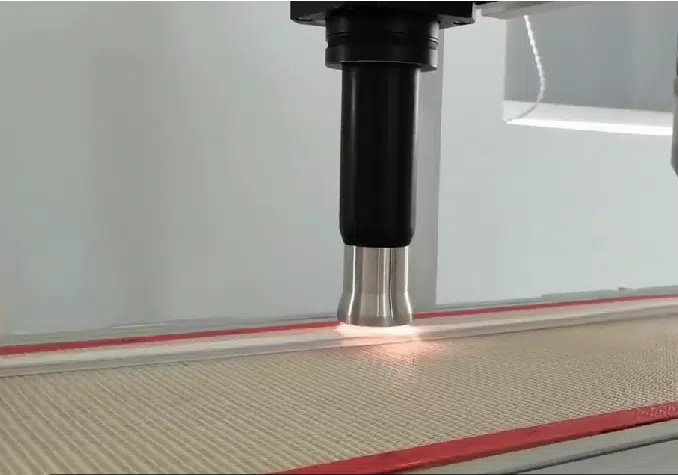

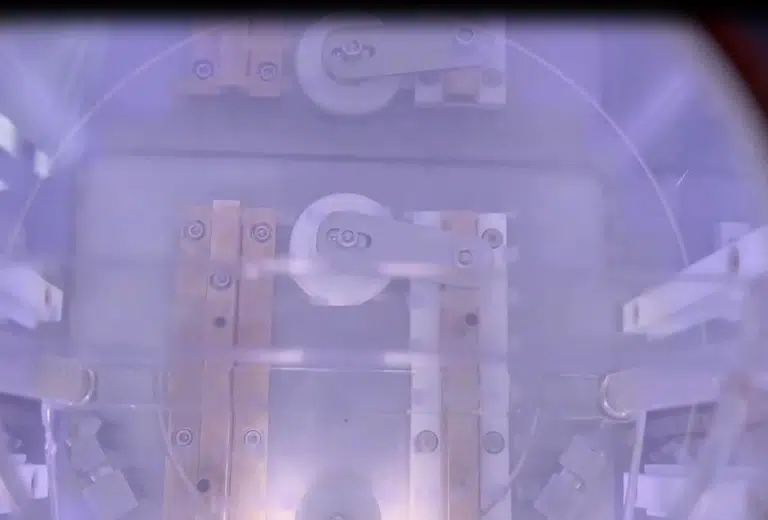

For the production process of cable, the use of plasma treatment is not only to effectively improve the adhesion of printing code , but also can fully fit the production line production. GM-2000 plasma treatment machine can efficiently meet high extrude speed 60-120 m/min. If you want support high speed, you can choose other model with multiquantity nozzles. But sometime it depend on the cable material and ink type. The model can match three size nozzle , 3-5mm, 7-13mm, 15-18mm, you can choose the nozzle size according to the height of inkjet code.

Please contact us if you meet the inkjet coding problem , not only the wire and cable ,but the printing for other plastic product.