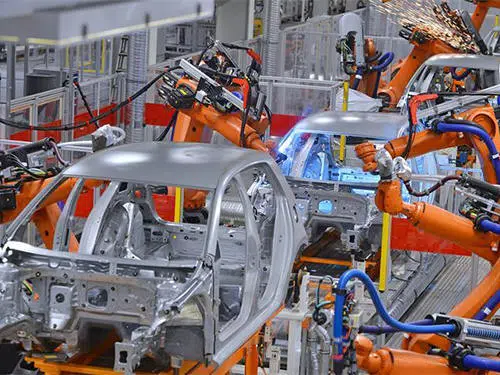

Most of the materials used in the automotive industry are PE, PP, PS and EPDM, and these materials have low surface energy and poor bonding properties. In bonding, coating, printing and cleaning, The effect is not good and the duration is not long. In order to solve this problem, it is necessary to use a plasma surface treatment machine. After treatment with plasma equipment, the chemical structure of the surface of the plastic material is changed, and the surface energy, adhesion and wettability of the product have been significantly improved. Plasma technology improves bonding reliability, improves coating or printing quality, and increases coating strength.

Plasma treatment improving the surface wettability and adhesion, which is applied in:

Focusing on the plasma treatment for 12 years.

Professional R&D team. School-enterprise cooperation

Free sample test. Each machine is tested before shipment. Professional technical training.

Accept private customization, included size, logo, color.

One year warranty and lifetime maintenance. Provide video guidance and online support beyond the warranty period.

Fari was founded in 2011, is a professional manufacturing enterprise specializing in the research and development, production, sales and promotion of vacuum plasma cleaner and atmospheric plasma surface treatment technology equipment.