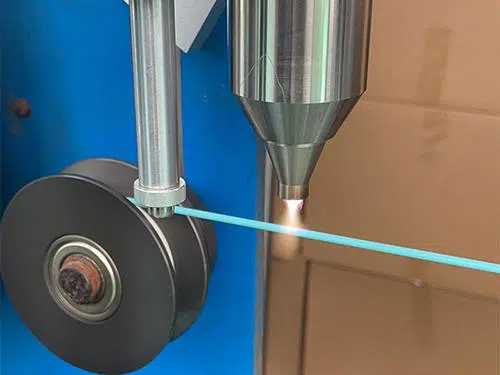

The cable industry has high requirements on the adhesion of inkjet inks, due to the special and complex material composition of many cable insulation layers. Problems such as missing codes and unclear codes often occur after printing codes with inkjet printers. In order to better solve the problem that the inkjet ink is easy to fall off, and without changing the currently used ink model, the surface of the insulating layer material is etched by the plasma generated by the plasma surface treatment equipment, so that the surface of the material becomes rough, and the material is greatly improved. The adhesion of the surface completely solves the problem that the ink will fall when scrubbed, improves the production capacity, and greatly reduces the production cost.

Plasma surface treatment machine is suitable for various materials of wire and cable, for example:

Focusing on the plasma treatment for 12 years.

Professional R&D team. School-enterprise cooperation

Free sample test. Each machine is tested before shipment. Professional technical training.

Accept private customization, included size, logo, color.

One year warranty and lifetime maintenance. Provide video guidance and online support beyond the warranty period.

Fari was founded in 2011, is a professional manufacturing enterprise specializing in the research and development, production, sales and promotion of vacuum plasma cleaner and atmospheric plasma surface treatment technology equipment.