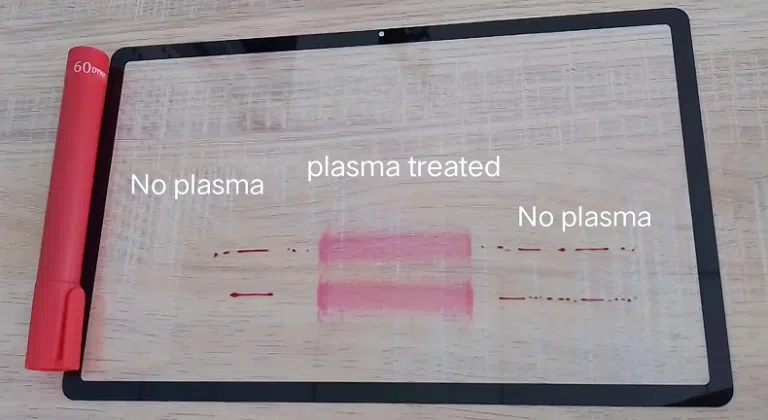

The surface treatment of LED lamp strip by plasma surface treatment machine has some unexpected effects. After just a few seconds of plasma bombardment, the adhesiveness and wettability of the lamp strip surface are greatly changed. Chemical crosslinking layers are created and oxygen-containing functional groups are introduced to make it fit better with the glue.

The part of the LED strip that needs plasma treatment is the silicone wrapped around the component. LED lamp belt is composed of FPC, LED, patch resistance, waterproof silicone, connecting terminals and other materials, the role of silicone can not only dust and moisture-proof, so that the internal is not easy to be corroded, but also because of its soft texture, can be bent, folded, wound arbitrarily, in irregular and narrow space can also be used normally. Therefore, it is very suitable for use in any combination of advertising decoration. However, silicone is a difficult material to bond in process production. The reason is that the surface of silicone is not sensitive, its intermolecular force is weak, surface energy is small, and viscosity is low. If not treated, the tape is difficult to adhere to the surface of silicone for a long time, resulting in the loss of LED lamp strip. Before contacting the plasma surface processor, some people believed that the problem of poor adhesion could be improved by changing better glue. However, in FARI’s past processing cases, the lamp strip would still fall off even if 3M double-sided adhesive was used for bonding.

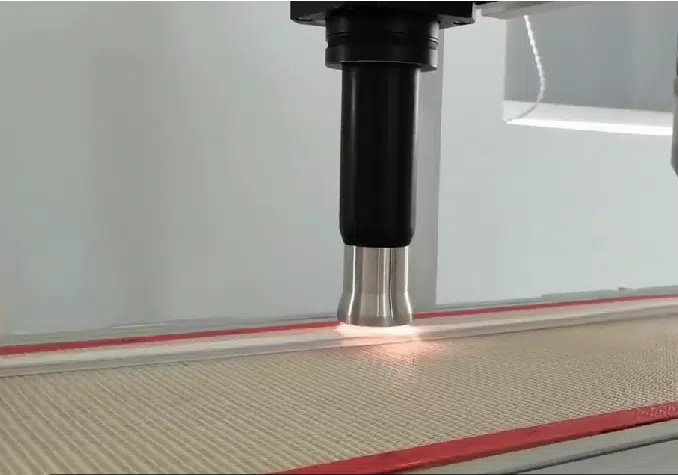

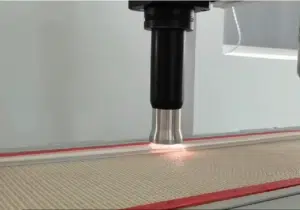

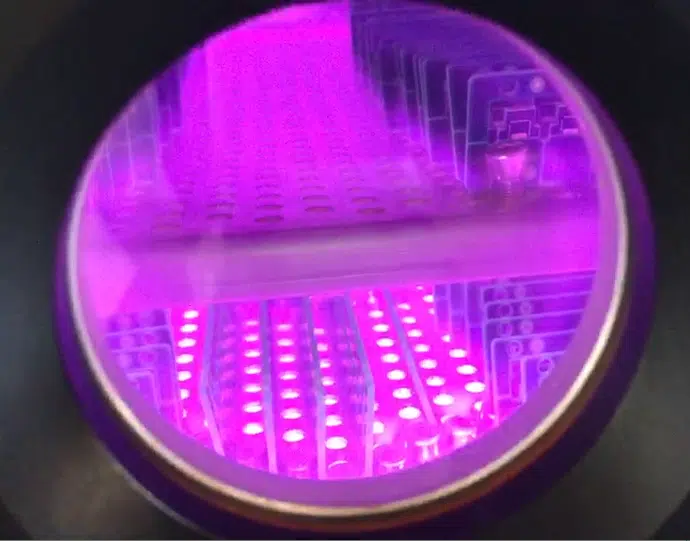

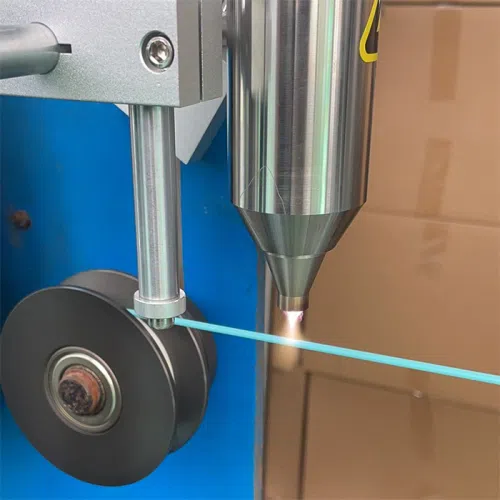

Plasma surface treatment silicone surface adhesion layer, through the air glow discharge between the two electrodes to form plasma, constantly and rapidly bombarding the surface of silicone material, break chemical bonds, so as to achieve the object surface etching, activation, cleaning and other purposes, in effect, the viscosity and adhesion of silicone surface will be significantly improved. Different silicone products need to be determined according to the shape of silicone and cleaning requirements. If the shape of the outer body of silicone is relatively flat, the atmospheric pressure plasma processor can be used for processing, but if it is irregular geometric shape, it needs to be processed by vacuum plasma cleaning machine. At present, plasma cleaning technology has a very mature system and scale, only through electrolytic air can achieve the desired effect, no other chemical pollution, easy to operate and efficient, is the ideal silicone material surface treatment.