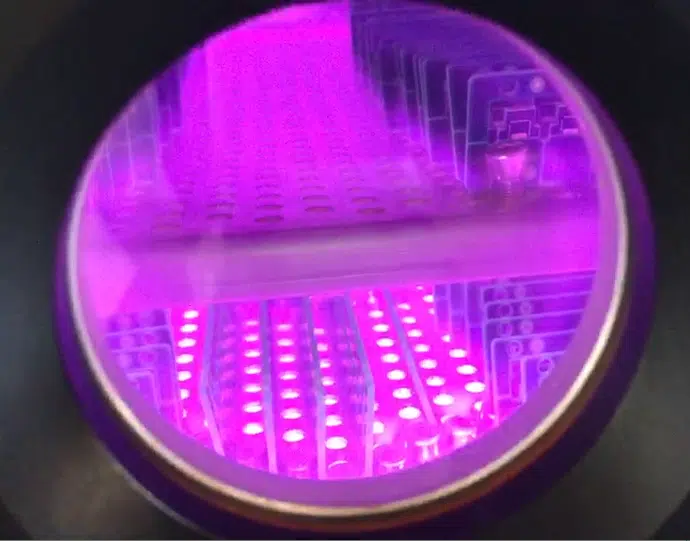

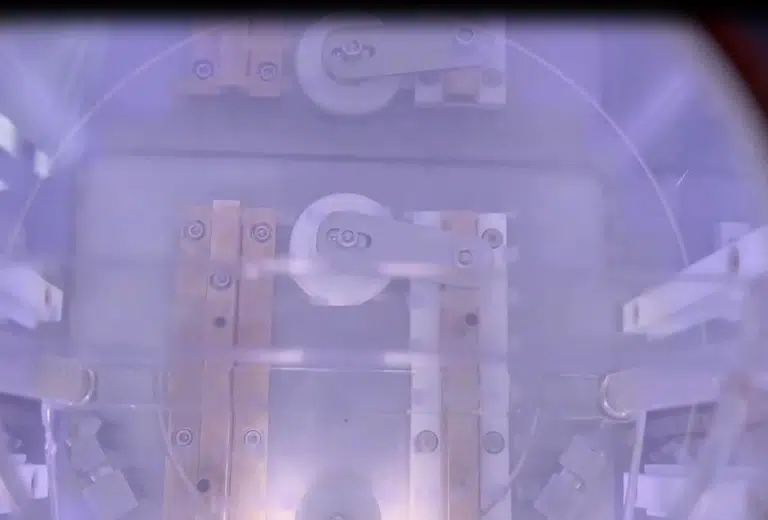

GD-10 plasma cleaning machine is with 10 L plasma chamber and 40 kHz IF power supply. The inside chamber has three trays which size is 175 x 185 cm. Three trays can achieve high efficiency treatment. At the same time , it can all-round treatment the irregular products with different size.

Vacuum plasma cleaner with PLC+touch screen control , it is convenient operation. About the treatment operation , it has two operation mode , manual mode and auto mode, you can choose the mode according your need.

The world’s first club was born in Scotland in the 15th century. After six centuries, the craftsmanship and materials of the golf clubs have changed dramatically. In the early stage of development, due to the limitations of resources and technology, most choose to use wood to make golf clubs, and the modern benefited from the development of science and technology, golf clubs generally pursue the material of light, strong pressure resistance, high hardness, corrosion resistance and other characteristics.

The materials that meet these requirements are: zinc, aluminum, stainless steel, carbon steel, titanium metal, iron-plated nickel alloy, etc. The golf rod head treated by the vacuum plasma cleaning machine is made of iron-plated nickel alloy.

Steel nickel plating has no pollution, no heavy metals, long cycle life, no electroplating equipment and other characteristics, good corrosion resistance is also excellent. At the same time, suitable for various shapes, various parts of steel materials; the coating density, low porosity, can improve many properties of the material, such as: strengthening strength, improve hardness, with super corrosion resistance, can exceed the use standard of stainless steel, and can save a lot of cost.

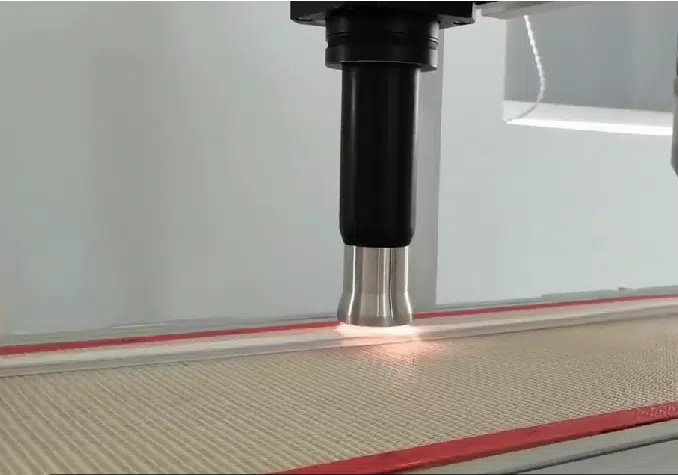

Today we share a case about plasma cleaning for clubs which to achieve strong gluing adhesion.

The energy of particles in plasma is generally about several to ten electron volts, greater than the binding bond energy of polymer materials (several to ten electron volts), can completely break the chemical bonds of organic macromolecules and form new bonds; but far lower than high-energy radiation rays, only involving the surface of the material, does not affect the performance of the matrix.

Through low-temperature plasma surface treatment, a variety of physical and chemical changes occur on the material surface, or produce etching and rough, or form a dense crosslinking layer, or introduce an oxygen-containing polar group, so that the hydrophilicity, bonding, chromability, biological compatibility and electrical properties are improved respectively. Under the appropriate process conditions, the surface of the surface form of the material has changed significantly. A variety of oxygen-containing groups are introduced to make the surface from non-polar, refractory to a certain polar, sticky and hydrophilic, which is conducive to bonding, coating and printing.

The model GD-10 vacuum plasma cleaning machine was apply in this case. Plasma cleaner not only can cleaning, modification, photoresist ash, improve the material surface adhesion, do not change the matrix performance, but also make the plasma uniform discharge and handle the surface of uneven products.

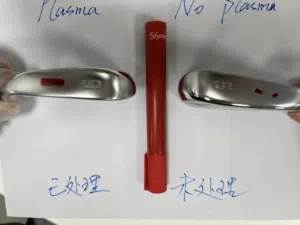

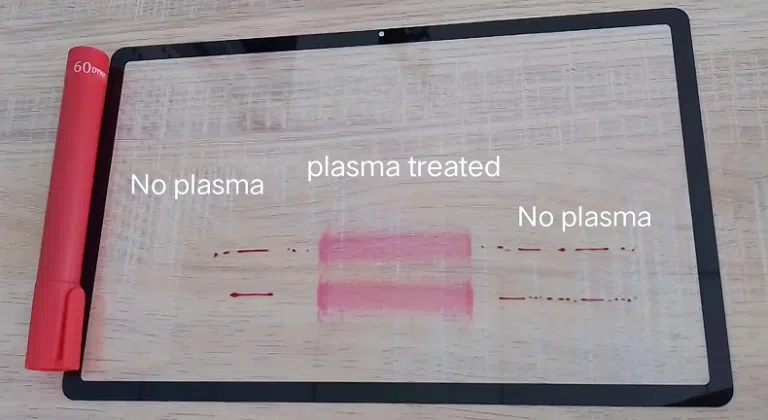

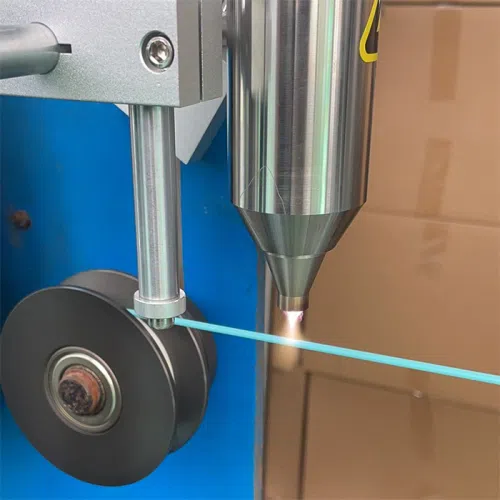

In this case , we using the dyne pen to test the material surface tension and adhesion. We using 56 dyne pen to scribe a long line slightly on the treating materials , after two seconds, it was form a glob that it means the surface tension can’t reach 56 dyne and can’t reach better gluing firmness. After plasma treated, we using the same dyne pen, there is no glob formed and does not spread all around, it means the surface tension reached or exceed 56 dyne that can reach better gluing firmness.

If you pursue refinement and quality of golf clubs , please contact us and we provide plasma technology for you. Welcome sent us inquiry.