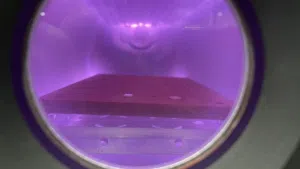

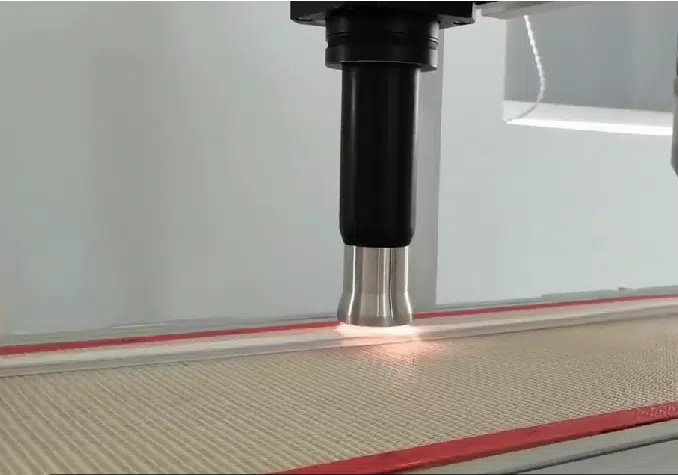

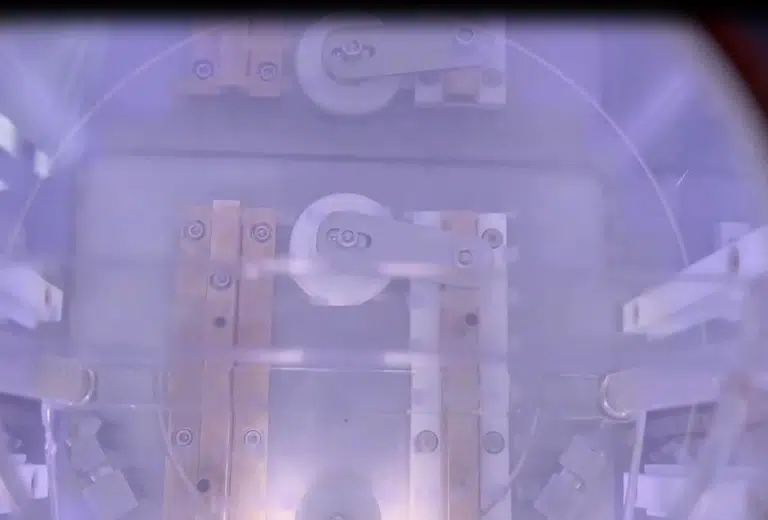

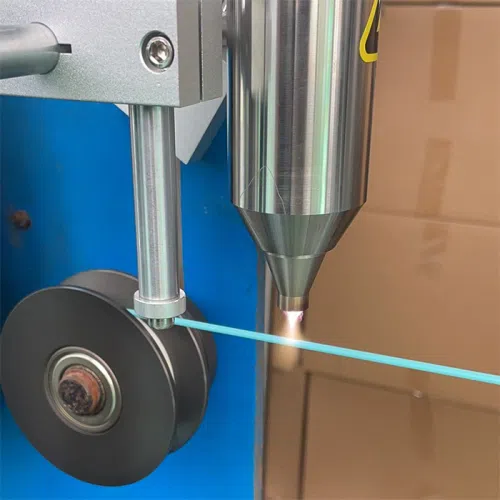

GD-10 RF plasma cleaning machine is with 10 L plasma chamber and 13.56 MHZ plasma generator which can producing stable and uniform plasma that better for modified, cleaning and etching material surface. The inside chamber has three trays which size is 175 x 185 mm. Three trays can achieve high efficiency treatment. At the same time, it can all-round treatment the irregular products with different size.

Vacuum plasma cleaner with PLC+touch screen control, it is convenient operation. About the treatment operation, it has two operation mode, manual mode and auto mode, you can choose the mode according your need.

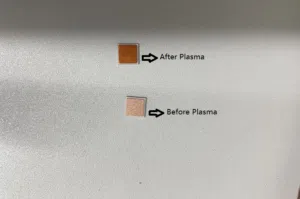

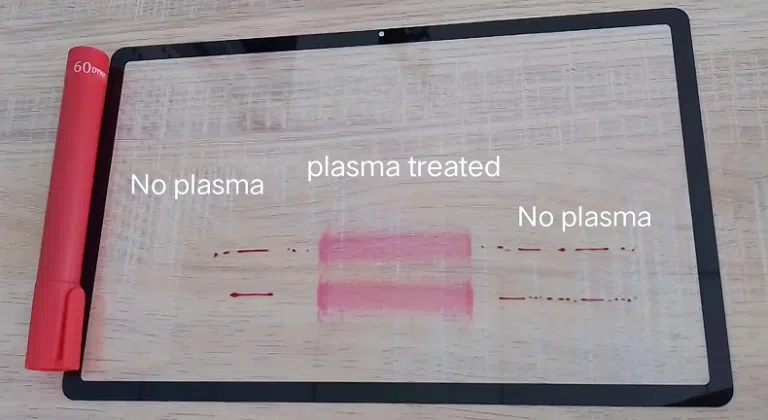

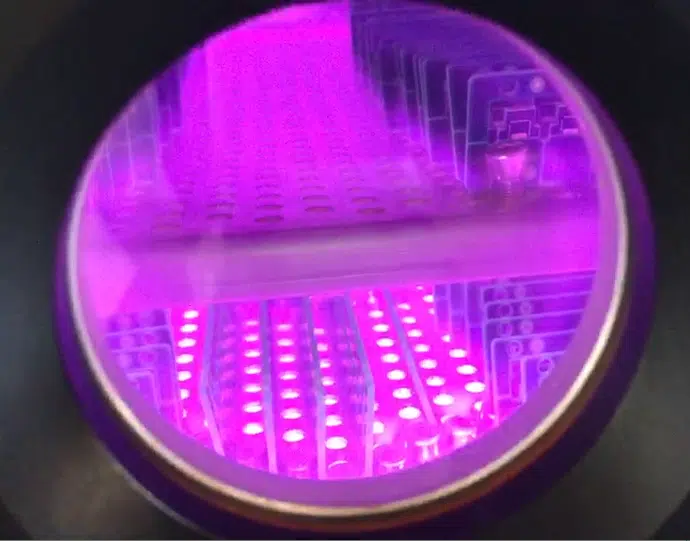

Plasma apply in redox is more and more mature. Today we share a case about the oxide reduction of copper. Copper is the best choose for applied in conductive material. But it is easy reactive with air at atmospheric pressure environment that producing the CuO and Cu2O which has a big influence of conductivity, signal transmission and the subsequent soldering. So there are many solution for oxide reduction, such as heating or reacting with hydrogen. But hydrogen is dangerous when transportation and keep save. While plasma can prodcuing the hydrogen indirectly.

Plasma is the fourth state of matter, it has including the H2. It will reacted with the oxide of copper when start plasma cleaning. There is a comparison before plasma & after plasma. It is obviously that the color is change after plasma treated. Oxide is successfully reduction.

Welcome to contact us if you need solving that kind problem. Of course , it is our honor if you can discuss more detail with us.