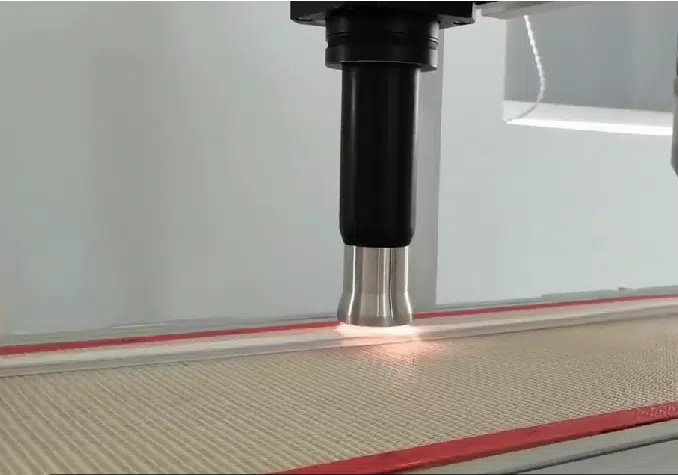

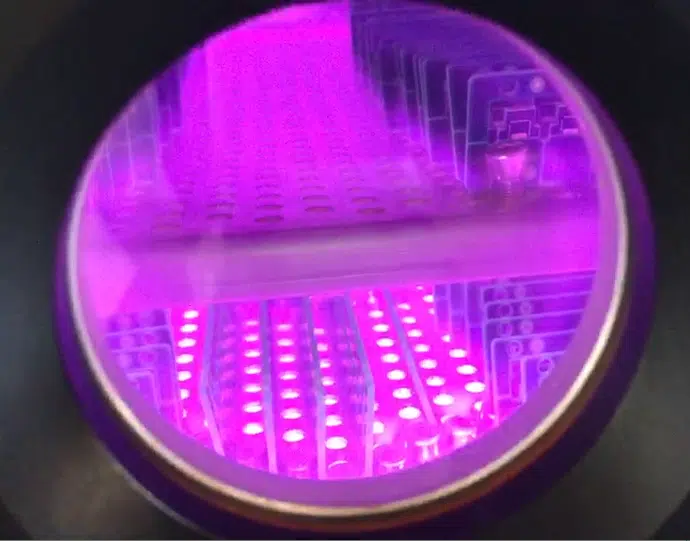

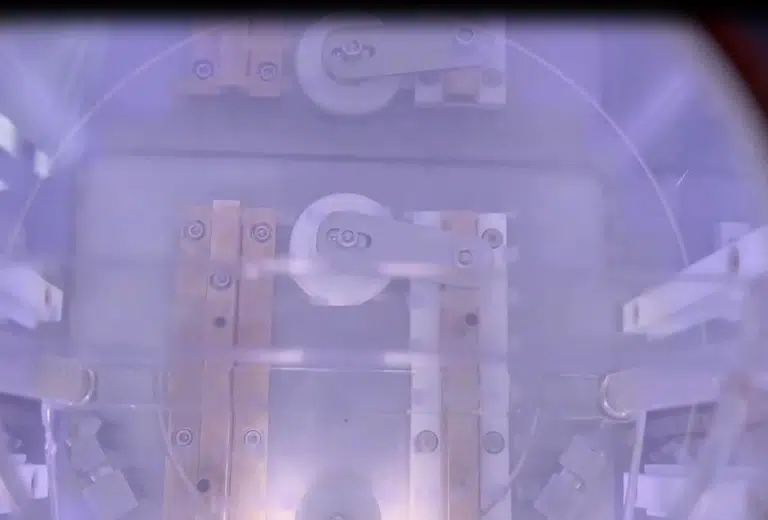

GD-10 plasma cleaning machine is with 10 L plasma chamber and 40 kHz IF power supply. The inside chamber has three trays which size is 175 x 185 cm. Three trays can achieve high efficiency treatment. At the same time , it can all-round treatment the irregular products with different size.

Vacuum plasma cleaner with PLC+touch screen control , it is convenient operation. About the treatment operation , it has two operation mode , manual mode and auto mode, you can choose the mode according your need.

Cell culture plate is also known as enzyme plate plate, the color is basically transparent, generally speaking, PS (polystyrene) is widely applied than PC. Because of its fragile , in recent years, there are many people choose to use in a variety of superior PC (polycarbonate) materials.

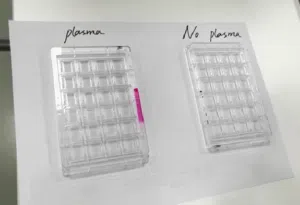

Cell culture plate, as a biological tool for cell culture, the culture plate should first be done decontamination treatment before cell culture to avoid the culture results affected by material contamination. Secondly, in the actual adherent cell culture experiment, because the adherent cells need to extend on the surface of the culture material to grow, the hydrophilicity of the culture vessel directly affects the growth of the cells. so not only ensure the sterilization of cell culture plate , but also to meet the high hydrophilicity.

However, this is not an easy thing, for these two requirements. In traditional process ,they are usually using chemical agent for cleaning. For general product, the use of chemical agent is enough, but if you want to apply in the field of biological medical, It not only cause subsequent treatment of pollution problem, residual chemical agent will also affect the results of the experiment. While plasma can reach requirement , convenient, fast and pollution-free.

Fangrui Technology has been focusing on the plasma cleaning industry for 12 years. We are business on atmospheric plasma surface treatment machine and vacuum plasma cleaning machine. About treatment the PC cell culture plate , we choose the GD-10 vacuum plasma cleaner.

Here are some advantages about plasma treatment:

- The modification effect only occurs on the surface of the material (about a few to dozens of nano), giving it one or more new functions without changing the inherent properties of the matrix;

- Regardless of the substrate type of the treatment object, such as metal, plastic, glass, polymer materials, can be treated;

- Simple process, convenient to operate, strong production controllability and high stability;

- Short treatment time, high reaction rate, and good uniformity of treatment;

- The whole process of dry treatment, no water consumption, no need to add chemical agents, no pollution.

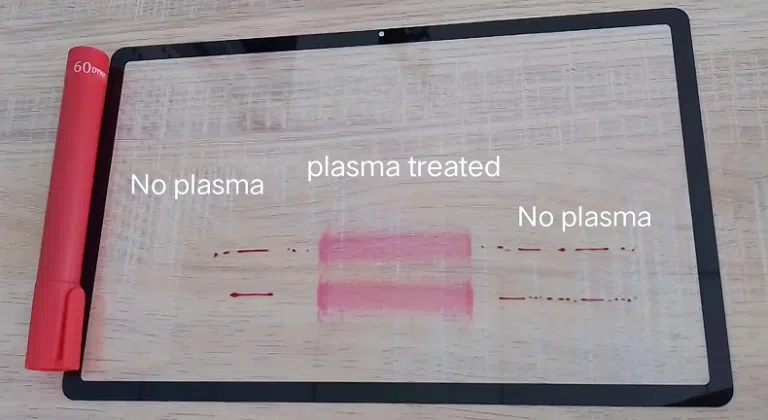

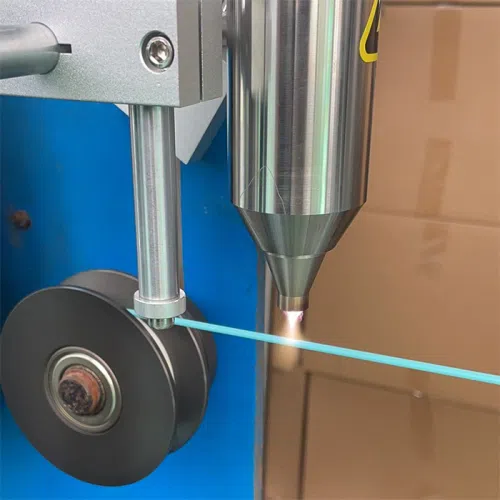

After plasma cleaning, the amount of organic contaminants on the surface of the cell culture plates was significantly greatly reduced when observed by the microscope. In the hydrophilic test, we used the 60 dyne pen for the test. The results showed that continuous line segments could be drawn on the surface of the product. To obtain more rigorous detection data, we also performed water droplet angle testing, which was tested on the material surface at 78.3 degrees before untreated, and reduced to 10.5 degrees after plasma cleaning.

In conclusion, PC cells treated with vacuum plasma surface plate can reduce the organic pollutants of the material and improve the surface hydrophilicity.

After we sent back the sample to customer, they give us positive feedback: the survival rate of cells can be reach 95% and the plasma can last long period than corona treatment. If you need treatment that kinds of product , welcome sent us inquiry!